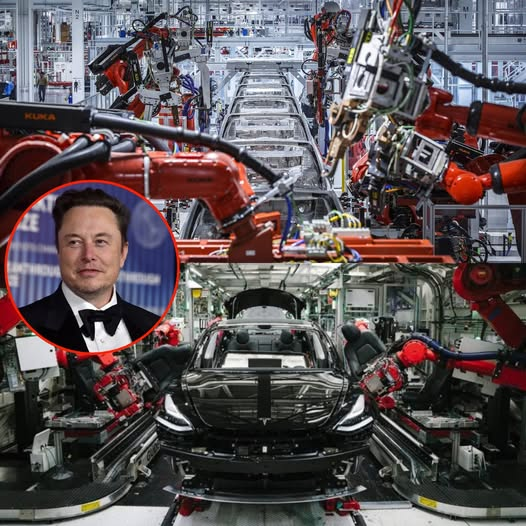

When Elon Musk first called Tesla’s future factories “alien dreadnoughts”, the world didn’t quite know what to make of it. The term conjured up visions of massive, sentient machines—extraterrestrial in appearance and capability—churning out vehicles with zero human involvement. It sounded like science fiction. But for Musk, it was a serious vision.

“We’re building the machine that builds the machine,” he once said. “And that machine should look like an alien dreadnought.”

At its core, Musk’s concept was radical: replace traditional assembly lines with fully automated, hyper-efficient factories, where robotic arms, AI-driven quality control systems, and modular automation work in seamless harmony. And while the road to that future has been anything but smooth, Tesla’s Gigafactories are steadily transforming the very nature of modern manufacturing.

Tesla’s first major leap toward the alien dreadnought began at its Fremont Factory in California, especially during the production ramp-up of the Model 3 in 2017. In pursuit of unmatched efficiency, Musk pushed for aggressive automation, filling the facility with cutting-edge robots and complex conveyance systems.

But instead of speeding things up, automation bottlenecks slowed everything down. Robots struggled with tasks better suited for humans. Conveyor belts jammed. The lines became so complex that they were nearly impossible to debug in real time.

Musk later admitted:

The next big leap came in 2019 with the opening of Gigafactory Shanghai, Tesla’s first major plant outside the U.S. Unlike Fremont, Shanghai was built from the ground up with the right balance of automation and manpower.By 2025, Gigafactory Texas—also known as Giga Austin—emerged as the closest realization of Musk’s alien dreadnought vision. Sprawling over 2,500 acres and housing the world’s largest die casting machines (the “Giga Press”), the plant represents Tesla’s most advanced production concept yet.